Blog Layout

Turning a Birdhouse on the Shopsmith Lathe

Feb 15, 2019

I took a 1x6 pine board and cut it into several equal lengths. Then I glued those pieces together. Which is easier said than it was done. Since the boards slide on the glue so easy when the clamps are applied, I had to glue it in stages. Gluing them two at a time and letting them dry, then gluing those stacks together two at a time and letting them dry. Then gluing the final two together to form one block. I needed two blocks, one larger for the bottom, and one a little wider but not as tall for the top. It took some time. Then I found the center and drilled a hole to accept my chucks worm screw in both blocks. Next I knocked off the corners as best I could with the saw. This makes life a bit safer and easier when turning larger pieces because I don’t have the hard corners to knock down. Plus it keeps the vibration from the spinning wood down.

And then it was time to begin turning the bottom part of the birdhouse. I got it rounded and cut the mortise which the jaws of the Nova chuck

would expand into to hold the piece as I hollowed out the inside of the birdhouse out. I must admit, hollowing larger pieces can be a challenge on the Shopsmith lathe because you have to have the support of the live center and tailstock to keep the piece from flying across the room. And that leaves very little room to work with your hollowing tools. I got it done though. At this point I only hollowed part way down.

Next I shaped the outside of the acorn bottom. This was far easier than hollowing it out I promise you. I used the parting tool to get started and cut a gap near the bottom. This way I could use my gouges to shape the bottom easier and not risk catching a gouge. on the wood left on the chuck. Once that was shaped I was able to finish hollowing and I’d know when to stop without going all the way through. Next I used the drill and a paddle bit to make the entry hole for the birdhouse, finished shaping the acorn bottom. Working up as close to a point as I could, and then I separated the birdhouse from the block that remained in the chuck.

I mounted the top of the birdhouse on the Shopsmith lathe and began to rough it down to round and began to shape it to look like the top of an acorn. Once I got a tenon cut on the top side, I flipped the acorn top and mounted the tenon into the chuck. On the opposite end I turned a tenon that would fit into the bottom of the acorn then began to hollow the top out. I didn’t need to hollow it as deep as the bottom so this was a little easier. I cut a stem on the side that was held by the Nova chuck, and drilled some holes in the stem with the intention of running a chain through to hang the birdhouse with. That plan changed later on though.

While my housemate painted the bottom, I used the Dremel rotary tool to stipple the top and make it look rough like the top of an acorn. Then I stained it brown. Once both the paint and stain were dry, I sprayed the birdhouse bottom and top with a couple coats of Polyurethane. Next I drilled a hole through the center of the stem and added an eye bolt with washers and a nut. This allowed me to either hang the birdhouse from a hook or use a chain to hang it from a branch. I drilled pilot hole through the top of the bottom and the tenon on the lid that fit down into the birdhouse and attached the acorn top to the bottom with screws. This way the screws can be removed and the top of the acorn lifted off to allow for cleaning between seasons. The video below is the video I submitted as the entry into the Summers Woodworking Birdhouse Challenge 2018. Please watch and enjoy.

Share

Tweet

Share

Mail

Redneck Know How Blog

By Donald Matthews

•

03 Jun, 2022

Every fisherman has his or her own favorite techniques to catch this beloved fish. Why is crappie, (or pomoxis, if you want to get scientific), are so beloved? Well, they give one heck of a fight when caught. A 2 lb. crappie can put up a fight to rival a bass of larger size. So catching them is fun. There is also the taste factor. Fried crappie tastes great.

By Donald Matthews

•

11 Oct, 2021

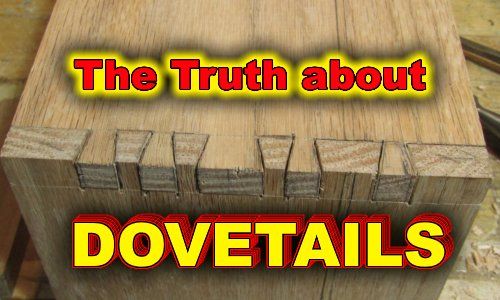

Everybody seems to be in love with dovetails these days. Myself included. They look nice, feel nice, and they make the woodworker feel an overwhelming since of pride when he makes tight and even. Especially the hand cut dovetails. Dovetail joints can be produced with power tools. And there are dovetail jigs you can buy and make. It makes getting precise dovetails with no gaps a lot easier. But nothing feels more satisfying than finally getting hand cut dovetails tight and gap free. And for the record, I use the term, “gap free”, very loosely. I’d wager that even the best woodworker gets gaps in their dovetails no matter how hard they try. Maybe not as many as us new to middlin’ woodworkers, and certainly not as noticeable, but there are gaps in their dovetails. Nowadays, people use dovetails not only as a joint, but as decoration. A showpiece if you will to show off the craftsmanship of the woodworker. But the reality is that they were not originally meant to be pretty. They were utilized to hold pieces that were heavily used together. Such as drawers or other parts of furniture and other items that were constantly pulled or tugged on. In the example below, you can see how the angles of the dovetails will keep the joint from coming apart during the tugging of the drawer when opening it. This part of the joint is where the dovetail joint get’s it’s name. Often when used on boxes, the orientation of those angles are switched around, placing them on the front of the box as a decoration, and the pins of the joint is put on the side. Great for looks, not so great for function. Of course for most smaller boxes, the function of the dovetail really isn’t needed and using dovetails for looks is fine and an anesthetically pleasing way to show off craftsmanship. But let’s not give up on using the dovetail joint for utilitarian purposes when building boxes too quickly. They can be a great way to join a bottom to a box that will be holding heavier stuff, such as tool boxes. The angle of the dovetails can manage the stresses of carrying heavier items such as tools if you wish to maintain a *NO screws or nails* policy on your woodworking projects. Or you can use the dovetail joint along with screws for extra protection against the bottom dropping out. So the purpose of the dovetail is a lot more than to just make your woodworking look good. In fact, long ago, they were hidden. Simply a way to join parts and give them the strength to do what the item was meant to do, and be hidden when the drawer was closed. Using the dovetail joint for decoration is a modern thing. Which I have nothing against. I love to show off dovetails I’ve made nearly perfect. Well, in my eyes anyway. Roy Underhill and Paul Sellers would likely just look at them and grin, maybe chuckle at me being so proud of something so far from the skill level they have achieved.