The Best CA Glue I’ve Used!

Strarbond Adhesives produce the best super glue you can buy.

I’ve been making some Celtic knot pens as of late. And was just about to finish preparing a batch of pen blanks when I decided I’d take the time to spread the word about the great Cyanoacrylate glue that I’ve been given the opportunity to promote. Starbond contacted me awhile back and offered to send me some of their Superglue and accelerator to try and possibly promote if I liked using it. Well, obviously I like it. The first thing I used it for was to glue the tubes into some pen blanks. I was a bit nervous because every C.A. glue I’d tried to use for this had failed while turning the pen. This can ruin your blank and your tube. At best create extra work and at worst ruin both the blank and the tube.

Starbond was the exception I’d been looking for! I really wanted an option that allowed me to start turning pens fairly soon after glueing in the tubes. I used Starbond Thick super glue to glue in the tubes for several pens. And turned most of them on the same day. My back failed me, not the Cyanoacrylate. Which amazed me because all other CA glues failed on the first or second pen. Starbond Thick Superglue held on all and held strong. I also used it to finish those pens.

Now CA glue finish on pens can be done with most any superglue. However, not every Cyanoacrylate will achieve the same result. Sometimes there may be a bit of cloudiness. This can come from many things, including the brand of glue. Some super glues don’t take the sanding and polishing as well as others. Sometimes the reaction between the accelerator and the ca causes it. None of these were an issue with the Starbond superglues . The finish sanded and polished to a crystal clear finish with a beautiful shine.

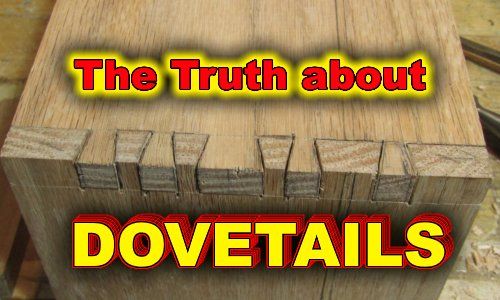

And finally to the Celtic knot pen blanks I mentioned in the beginning. The trick with a Celtic knot is keeping your cuts and glue ups as square as possible. This helps insure you get a straight bore through the center of the blank, which is very important to having a even and nice looking knot. On the one in the pictures, I’m attempting to make a more complex, multi-knot effect.

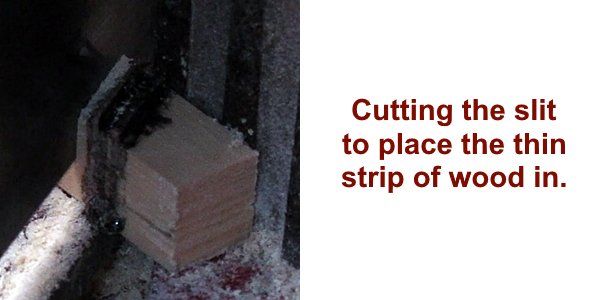

I start by cutting a slit, most of the way through the blank, but not all the way through it. Not cutting completely through the blank aids in the gluing in of the thin pieces of wood. Gluing up a pen blank can be difficult with a straight cut. Gluing up one with an angled cut like these cuts will pull out bad words you didn’t even think you knew while creating new ones.

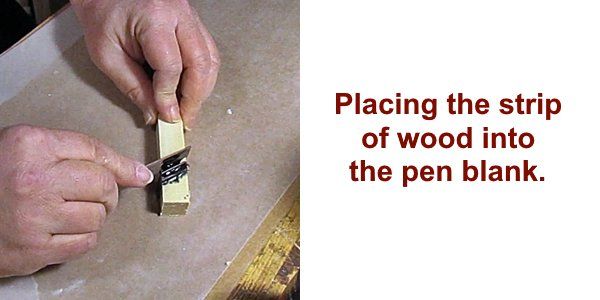

Then I glue the thin pieces of wood into the slit I’ve cut on the blank. I used one of Starbond's tinted CA glues for this. They have these in brown and black. I chose black to try and highlight the brown wood I was using. I put a little bit on each side of the thin cut wood and pushed it down into the slit I had cut previously. Then I spray it with some accelerator and give it just a few minutes to dry. Then I take it back to the saw and cut another slit just below the one I just did. I continue this until I get 4 strips of wood superglued in. Then I flip it over and continue the same process on all sides.

I haven’t turned that one yet, but here’s the result from a previous pen in which I only did two opposing sides with the multiple cuts and one cut on the other two sides. I highly recommend you give Starbond Super Glue a try. And if you use the word code “WOODSHOP” , you get a 10% discount on your order.

Slide title

Cutting the slit to place the thin strip of wood in.

Button

Slide title

Putting some Starbond Black CA glue on the strip of wood.

Button

Slide title

Placing the strip of wood into the pen blank.

Button

Slide title

The finished Celtic Knot pen blank.

Button

Redneck Know How Blog