Blog Layout

Deciding on a Fixed Blade Broadhead

Web DevObal • Jan 24, 2016

Fixed Blade Broadheads for bow hunting!

When searching for the best fixed blade broadheads I found the Grim Reaper Hades was the most accurate, quietest flying and deepest penetrating. It’s not your ordinary fixed blade broadhead. This broadheads blades are sharpened to cut whether going in or out, with a bone crushing solid stainless steel v-notch tip and 4 point blade locking system making the Hades the best flying, best penetrating fixed blade in my experiance!

A bad choice in a broadhead can mean you being depressed about that prize deer that got away and was never found after being hit with a good shot from a poor choice broadhead. Here are a few tips I’ve learned along the way that helps me make the right choice in fixed blade broadheads.

Bowhunters have some very powerful bows available to them nowadays. But even with those powerful bows used with a mid-weight arrow and speeds beyond 265 fps, some fixed blade broadheads won’t do well in flight without fine tuning it. Not very often does a bow hunter take the time to tune their broadhead. But they should take the time to sit and play with testing and tuning the broadheads and arrows to get the perfect aerodynamics.

Accuracy:

Use three fixed blade broadheads on three arrows making sure they are seated and aligned to the arrow shaft perfectly, and three arrows with field points. Then start group shooting at a distance of 40 to 50 yards with three field points, then with the three fixed blade broadheads. If the broadheads are off more than 5 or 6 inches from the field point groups, you probably don’t want to use those broadheads for hunting. With a well-tuned bow and perfectly matched fixed blade broadheads, you should easily group within 5 or 6 inches and be very close to the impact points of the field points. A general rule of thumb is that shorter fixed blade broadheads can be pushed faster with less planning problems.

Durability and Strength:

Durability is very important in fixed blade broadheads. You’ll already be putting some wear on the broadhead by checking for accuracy during practice and other such hunting preparation. It is wise to change the blades of your broadhead after accuracy tests. Fixed blade broadheads made of poor quality aluminum won’t last thorough pre-hunt practice. Broadheads with all-steel or titanium ferrules are far better and will last much longer. A good test for the durability and strength of fixed blade broadheads is to shoot them through a piece of sheet metal that is about an eighth of an inch thick. Any signs of damage here such as blades dislodging or coming off will tell you if the broadhead can be depended on during a hard hit against a bone.

Penetration:

A fixed blade broadhead should go in deep and stay in line with the point of entry no matter what angle. Wild game have a tendency to twist or jump right after the arrow is released even when the best shot is chosen, so the bowhunter should plan for the worst. You can test the design of the fixed blade broadhead by shooting it into plywood at different angles. Broadheads with slim noses and less angle to the blade seem to work better, however this may need to be adjusted depending on the arrow speed. Broadheads that have more of an angle to the blade tend to cause problems because the blade closest to the target hits before the point and the whole broadhead and arrow is deflected.

Sharpness:

Rub a piece of cowhide against the blade of your fixed blade broadhead. If it doesn’t cut with just a light touch, it’s too dull. A sharp broadhead blade will cause the deer to bleed excessively and that loss of blood means a quicker kill. Fixed blade broadheads with replaceable blades are preferred however there are some broadheads with non-replaceable blades that work well, and can be re-sharpened successfully.

Cutting Surface:

For better and more effective wound channels, a broadhead with 3 inches of sharp cutting surface is best. Such fixed blade broadheads generally come with fairly wide cutting widths. A broadhead has to travel through several layers of tough tissue that will dull the blades before getting to the vital areas which is slick and rubbery, but contain many blood vessels. It takes a fixed blade broadhead that will stand up to those first layers, which likely will include passing through the ribs, and remain sharp in order to cut those vital areas and open up those blood vessels. And a dull broadhead blade can cause tissue to swell and seal up which will hinder bleeding.

Concentricity:

Take your fixed blade broadhead and screw it on an arrow, if everything is correct, you should be able to spin it on the broadheads tip like a top with very little wobble. If too much wobble is present, try the broadhead on a different arrow. All-steel and titanium fixed blade broadheads tend to be easier to match with and arrow shaft because of their solid one piece tip and ferrule design. Aluminum ferrule Broadheads that use a screw-on or press fit tip tend to need more mixing and matching.

I hope this article about fixed blade broadheads has been helpful in helping you find the right broadheads for your bowhunting needs. It can be a very rewarding and satisfying to bowhunt with the right fixed blade broadhead. Thank you for reading. And please take time to visit my sponsors by clicking on their banners. Each carries some great fixed blade broadheads or other bowhunting gear that will help make your bowhunting experience more successful.

Share

Tweet

Share

Mail

Redneck Know How Blog

By Donald Matthews

•

03 Jun, 2022

Every fisherman has his or her own favorite techniques to catch this beloved fish. Why is crappie, (or pomoxis, if you want to get scientific), are so beloved? Well, they give one heck of a fight when caught. A 2 lb. crappie can put up a fight to rival a bass of larger size. So catching them is fun. There is also the taste factor. Fried crappie tastes great.

By Donald Matthews

•

11 Oct, 2021

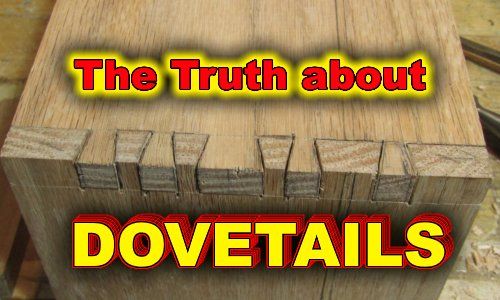

Everybody seems to be in love with dovetails these days. Myself included. They look nice, feel nice, and they make the woodworker feel an overwhelming since of pride when he makes tight and even. Especially the hand cut dovetails. Dovetail joints can be produced with power tools. And there are dovetail jigs you can buy and make. It makes getting precise dovetails with no gaps a lot easier. But nothing feels more satisfying than finally getting hand cut dovetails tight and gap free. And for the record, I use the term, “gap free”, very loosely. I’d wager that even the best woodworker gets gaps in their dovetails no matter how hard they try. Maybe not as many as us new to middlin’ woodworkers, and certainly not as noticeable, but there are gaps in their dovetails. Nowadays, people use dovetails not only as a joint, but as decoration. A showpiece if you will to show off the craftsmanship of the woodworker. But the reality is that they were not originally meant to be pretty. They were utilized to hold pieces that were heavily used together. Such as drawers or other parts of furniture and other items that were constantly pulled or tugged on. In the example below, you can see how the angles of the dovetails will keep the joint from coming apart during the tugging of the drawer when opening it. This part of the joint is where the dovetail joint get’s it’s name. Often when used on boxes, the orientation of those angles are switched around, placing them on the front of the box as a decoration, and the pins of the joint is put on the side. Great for looks, not so great for function. Of course for most smaller boxes, the function of the dovetail really isn’t needed and using dovetails for looks is fine and an anesthetically pleasing way to show off craftsmanship. But let’s not give up on using the dovetail joint for utilitarian purposes when building boxes too quickly. They can be a great way to join a bottom to a box that will be holding heavier stuff, such as tool boxes. The angle of the dovetails can manage the stresses of carrying heavier items such as tools if you wish to maintain a *NO screws or nails* policy on your woodworking projects. Or you can use the dovetail joint along with screws for extra protection against the bottom dropping out. So the purpose of the dovetail is a lot more than to just make your woodworking look good. In fact, long ago, they were hidden. Simply a way to join parts and give them the strength to do what the item was meant to do, and be hidden when the drawer was closed. Using the dovetail joint for decoration is a modern thing. Which I have nothing against. I love to show off dovetails I’ve made nearly perfect. Well, in my eyes anyway. Roy Underhill and Paul Sellers would likely just look at them and grin, maybe chuckle at me being so proud of something so far from the skill level they have achieved.