Shopsmith Bandsaw Blade Tracking

October 6, 2015

How to get the blade to track properly on the Shopsmith bandsaw

Are you having problems with the tires, blade, or both coming off your Shopsmith bandsaw? I’m going to try and help you by explaining how the bandsaw blade should track in your Shopsmith Bandsaw.

If you’ve had problems with the tire coming off your Shopsmith bandsaw or the blade coming off, sometimes even both; you may have gone down the same route as I did. Replaced the tires and still the same thing happens. Maybe you’ve gotten the Shopsmith used and it came to you with the wrong size blades, or no blades at all. Maybe no instructions either. So you search to find what size bandsaw blade to use.

You go to the forums to seek advice and you find where they say you should use a 72 inch blade Shopsmith bandsaw blades. You can use other blade brands but the must be within a half inch of that 72 inches. But leave out the key information that you will have to adjust the tension differently than what the tension scale on the machine says to adjust for that difference in length. They just assume everyone would know or think to do adjust the tension.

You may be like I am and simply like to build things out of wood. You simply like woodworking and just want the bandsaw to work without having to go back to school to get a mechanical engineering degree to understand how to keep the blade on your bandsaw. I mean come on, there’s a reason I build things out of wood and not metal. Yet there seems to be a need for that engineering degree where you go to get help.

Please understand, those people are good folks that really are trying to help you. But they seem to get caught up the technical and mathematical bits when they are trying to help you and end up going all around, past, and beyond what you really need to know in simple and basic terms. Friends that had bandsaws were offering me advice and, unfortunately, the advice they had which was good advice for other brands of bandsaws, was wrong advice for the Shopsmith. It simply throws people who have never used the Shopsmith bandsaw to see the blade ride the back of the wheel. But that indeed is where it’s supposed to be.

That is why I made the videos below. I could find plenty of videos showing how to cut, how to adjust the fence, and lord knows, plenty of videos of people pushing wood through it. But none that really walked me through the alignment of the blade. So I did my best to explain what I have learned about alignment of the roller bearings, blade guides, and placement of the blades. I hope these help you get your Shopsmith bandsaw in condition to make some sawdust and build some beautiful woodworking projects. And below the videos are some links to bandsaw blades that will work on your Shopsmith bandsaw. Any purchase you make through those links help support this website and my youtube channel, helping me bring content to you.

Video #1 - Shopsmith Bandsaw How the Blade Should Track

Video #2 - Shopsmith Bandsaw How the Blade Should Track Part 2

Redneck Know How Blog

Every fisherman has his or her own favorite techniques to catch this beloved fish. Why is crappie, (or pomoxis, if you want to get scientific), are so beloved? Well, they give one heck of a fight when caught. A 2 lb. crappie can put up a fight to rival a bass of larger size. So catching them is fun. There is also the taste factor. Fried crappie tastes great.

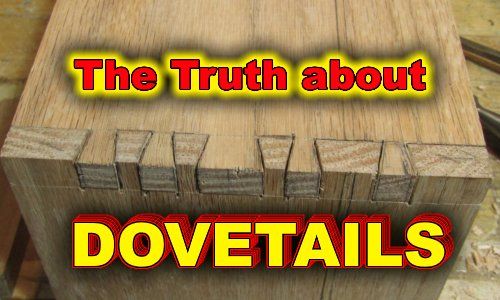

Everybody seems to be in love with dovetails these days. Myself included. They look nice, feel nice, and they make the woodworker feel an overwhelming since of pride when he makes tight and even. Especially the hand cut dovetails. Dovetail joints can be produced with power tools. And there are dovetail jigs you can buy and make. It makes getting precise dovetails with no gaps a lot easier. But nothing feels more satisfying than finally getting hand cut dovetails tight and gap free. And for the record, I use the term, “gap free”, very loosely. I’d wager that even the best woodworker gets gaps in their dovetails no matter how hard they try. Maybe not as many as us new to middlin’ woodworkers, and certainly not as noticeable, but there are gaps in their dovetails. Nowadays, people use dovetails not only as a joint, but as decoration. A showpiece if you will to show off the craftsmanship of the woodworker. But the reality is that they were not originally meant to be pretty. They were utilized to hold pieces that were heavily used together. Such as drawers or other parts of furniture and other items that were constantly pulled or tugged on. In the example below, you can see how the angles of the dovetails will keep the joint from coming apart during the tugging of the drawer when opening it. This part of the joint is where the dovetail joint get’s it’s name. Often when used on boxes, the orientation of those angles are switched around, placing them on the front of the box as a decoration, and the pins of the joint is put on the side. Great for looks, not so great for function. Of course for most smaller boxes, the function of the dovetail really isn’t needed and using dovetails for looks is fine and an anesthetically pleasing way to show off craftsmanship. But let’s not give up on using the dovetail joint for utilitarian purposes when building boxes too quickly. They can be a great way to join a bottom to a box that will be holding heavier stuff, such as tool boxes. The angle of the dovetails can manage the stresses of carrying heavier items such as tools if you wish to maintain a *NO screws or nails* policy on your woodworking projects. Or you can use the dovetail joint along with screws for extra protection against the bottom dropping out. So the purpose of the dovetail is a lot more than to just make your woodworking look good. In fact, long ago, they were hidden. Simply a way to join parts and give them the strength to do what the item was meant to do, and be hidden when the drawer was closed. Using the dovetail joint for decoration is a modern thing. Which I have nothing against. I love to show off dovetails I’ve made nearly perfect. Well, in my eyes anyway. Roy Underhill and Paul Sellers would likely just look at them and grin, maybe chuckle at me being so proud of something so far from the skill level they have achieved.