How to Make Wooden Curtain Rod Holders

August 13, 2017

I moved into the new house and the need for curtains of became obvious real quick. I doubt the neighbors would appreciate seeing me in nothing but my drawers or even less. We looked around for some less expensive metal curtain rod holders, but even the less expensive ones were ugly (to me) and not what I’d consider inexpensive. After cleaning up my shop and getting thing where I could work a little. I ripped a 2x 4 in half and began working on some of my own.

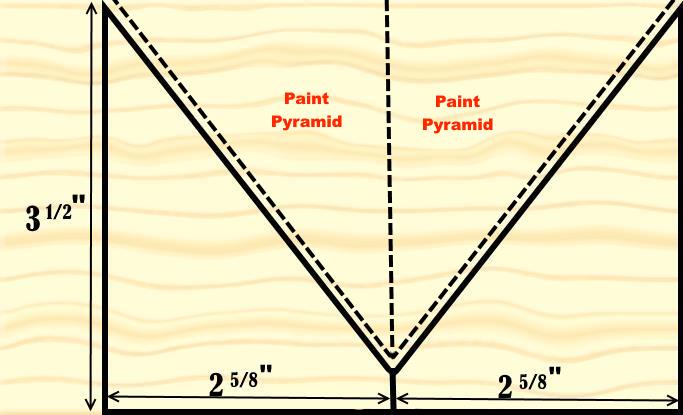

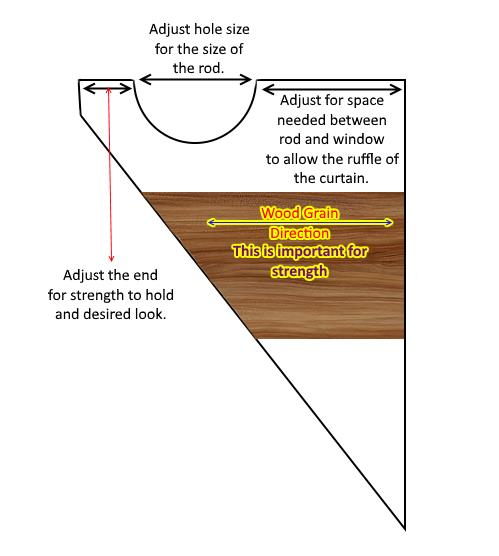

My roommate had drawn up an idea. A rectangle split from top right corner to bottom left corner, creating two right triangles. Which was a great idea, however, I needed some more paint pyramids so turning them the way I did in the picture allowed me to get theses from the triangle of waste material. Also, for astatic purposes, I thought it would look better if the grain on the top of both holders come from the same side of the board.

I also felt the grain should run from front to back on the curtain rod holders. If the grain runs from top to bottom, the weight of the rod and curtain might split it easier if the grain is top to bottom. There are some thin spots under the hole that holds the rod and that can make for a weak spot, especially if the grain isn’t oriented correctly. So I had to sacrifice some material. But making the paint pyramids made it not so much of a sacrifice. It was a scrap piece of pine 2x4, so I wasn’t really stressing the waste so much. Had it been walnut, cherry, or something of the like I might have cried a bit more.

I marked it out on the wood being sure to allow for the kerf of the saw blade. (If you’re not sure exactly what “kerf” is, I explain it in this video... http://redneckknowhow.com/Blog/BlogMain/ArticleID/216/saw_kerf

) Now that I had them laid out, it was time to cut the rod holders out. Naturally, this can be done on the table saw, but I just needed 4 curtain rod holders at the moment so I used the handsaw. I used the end of the board for the back of the first curtain rod holder, so I started cutting down the center of the two. On this cut I went straight down the center of the line trying to keep the waste equal on both sides. Then onto the back of the other rod holder. Here is where allowing for the saw kerf is really important. Cut to the waste side of the line between sets of rod holders. If you are cutting multiple sets of rod holders side by side, be sure to leave a gap the width of your saw kerf to allow for that waste. If you don’t allow for the saw kerf your measurements may be slightly off on the final project. Likely not enough to be noticed after the curtain is hanged, but this can be a problem when making boxes or drawers so I like to stay in the habit of allowing for that kerf even when it really doesn’t matter that much. Then simply cut the corner of the board that is attached to the curtain rod holder.

So now comes cutting the round notch that will actually hold the curtain rod. I’d love to be able to say that I used some fancy algebra, ungodly math formula, or even some genius magic to get the size and placement for this notch. The simple fact of the matter is that I used a nickel and a ruler. I placed the nickel where I thought the notch should be, and traced the circumference. Then used the ruler to continue to the top from the widest part of the nickel mark. Then measured the depth of the notch; the length from the back of the rod holder to where the notch met the top; then used those measurements to mark the rest of the curtain rod holders.

I used the Dremel Moto-Saw to cut these notches. This was the first thing I’ve used it on and was very impressed at how easily it cut through that thickness of board. Granted it was softwood but I was still impressed at how good of a cut I got. There’s multiple ways to cut these notches, this just happened to be the easiest way I had available. The moto-saw is basically a scrollsaw so I’m sure if you have a regular scrollsaw it will work the same provided it will cut that thickness of wood. You could also use a forstner bit on a drillpress for the circle and remove the the remaining waste with a bandsaw or copping saw. However you can or so choose to get it done is fine.

If you’re rounding the edges of the curtain rod holders by sanding, it’s fine to go ahead and drill the holes first, before sanding. However if you shape the edges with the router I think it’s best to drill the holes after you shape the edges of your rod holders to prevent tear-out around the area where the screw-holes are.

I decided on the best places for the screws in order to hold the rod holders to the window frame, and placed one an inch from the bottom of the holder; another an inch up from that. I drilled twice. Once going all the way through using a smaller bit which the screw will actually go through to hold, and a larger hole over that to countersink. I drilled the smaller hole, then measured with the screw how far to go down with the counter sink. I want the screw to have enough coming through to grip and hold the window frame, and the head of the screw will tighten against the bottom of the larger hole. This will keep the head of the screw from being so easily visible on the curtain rod holder.

All that’s left is a final sanding to knock off any rough spots that may have accrued, then finish. On the first ones I stained with a red chestnut stain then finished it with a few coats of clear spray shellac. On the second I simply used boiled linseed oil. Let dry and hung the curtains. Thank you for visiting Redneck Know How and please take a look around. I have loads of other stuff and new articles on the way.

Redneck Know How Blog

Every fisherman has his or her own favorite techniques to catch this beloved fish. Why is crappie, (or pomoxis, if you want to get scientific), are so beloved? Well, they give one heck of a fight when caught. A 2 lb. crappie can put up a fight to rival a bass of larger size. So catching them is fun. There is also the taste factor. Fried crappie tastes great.

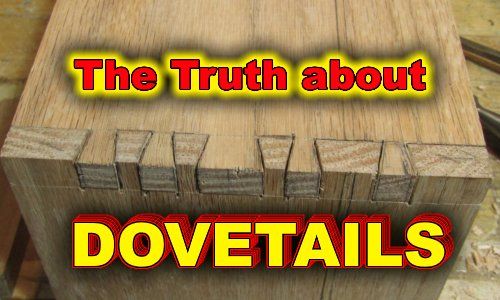

Everybody seems to be in love with dovetails these days. Myself included. They look nice, feel nice, and they make the woodworker feel an overwhelming since of pride when he makes tight and even. Especially the hand cut dovetails. Dovetail joints can be produced with power tools. And there are dovetail jigs you can buy and make. It makes getting precise dovetails with no gaps a lot easier. But nothing feels more satisfying than finally getting hand cut dovetails tight and gap free. And for the record, I use the term, “gap free”, very loosely. I’d wager that even the best woodworker gets gaps in their dovetails no matter how hard they try. Maybe not as many as us new to middlin’ woodworkers, and certainly not as noticeable, but there are gaps in their dovetails. Nowadays, people use dovetails not only as a joint, but as decoration. A showpiece if you will to show off the craftsmanship of the woodworker. But the reality is that they were not originally meant to be pretty. They were utilized to hold pieces that were heavily used together. Such as drawers or other parts of furniture and other items that were constantly pulled or tugged on. In the example below, you can see how the angles of the dovetails will keep the joint from coming apart during the tugging of the drawer when opening it. This part of the joint is where the dovetail joint get’s it’s name. Often when used on boxes, the orientation of those angles are switched around, placing them on the front of the box as a decoration, and the pins of the joint is put on the side. Great for looks, not so great for function. Of course for most smaller boxes, the function of the dovetail really isn’t needed and using dovetails for looks is fine and an anesthetically pleasing way to show off craftsmanship. But let’s not give up on using the dovetail joint for utilitarian purposes when building boxes too quickly. They can be a great way to join a bottom to a box that will be holding heavier stuff, such as tool boxes. The angle of the dovetails can manage the stresses of carrying heavier items such as tools if you wish to maintain a *NO screws or nails* policy on your woodworking projects. Or you can use the dovetail joint along with screws for extra protection against the bottom dropping out. So the purpose of the dovetail is a lot more than to just make your woodworking look good. In fact, long ago, they were hidden. Simply a way to join parts and give them the strength to do what the item was meant to do, and be hidden when the drawer was closed. Using the dovetail joint for decoration is a modern thing. Which I have nothing against. I love to show off dovetails I’ve made nearly perfect. Well, in my eyes anyway. Roy Underhill and Paul Sellers would likely just look at them and grin, maybe chuckle at me being so proud of something so far from the skill level they have achieved.